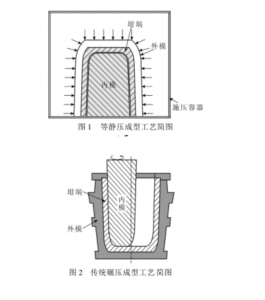

Imveliso ye-graphite crucible iye yavela kakhulu ngokufika kwetekhnoloji yokucinezela isostatic, iphawula ukuba yeyona ndlela iphambili kwihlabathi.Xa kuthelekiswa neendlela zesiqhelo zokunqanda, ukucinezela kwe-isostatic kuphumela kwiicrucibles ezinokwakheka okufanayo, ukuxinana okuphezulu, ukusebenza kakuhle kwamandla, kunye nokuchasana okuphezulu kwi-oxidation.Ukusetyenziswa koxinzelelo oluphezulu ngexesha lokubumba kwandisa kakhulu ukuthungwa kwe-crucible, ukunciphisa i-porosity kwaye emva koko kukhulise i-thermal conductivity kunye nokuchasana kwe-corrosion, njengoko kuboniswe kuMzobo 1. Kwindawo ye-isostatic, inxalenye nganye ye-crucible ifumana uxinzelelo olufanayo lokubumba, ukuqinisekisa ukuhambelana kwezinto kuyo yonke indawo.Le ndlela, njengoko ibonisiwe kuMfanekiso 2, igqwesa inkqubo yesiqhelo yokunqanda, ekhokelela kuphuculo olukhulu ekusebenzeni okunqamlezileyo.

1. Ingxelo yeNgxaki

Inkxalabo ivela kumxholo we-aluminiyam yealloyi yokugquma isithando somlilo somlilo sisebenzisa iicrucible zegraphite ezinqamlezileyo, ezinobomi obumalunga neentsuku ezingama-45.Emva kweentsuku ezingama-20 kuphela zokusetyenziswa, ukuhla okubonakalayo kwe-thermal conductivity kubonwa, kunye nokuqhekeka kwe-micro-cracks kwindawo yangaphandle ye-crucible.Kwiinqanaba zokugqibela zokusetyenziswa, ukuhla okukhulu kwi-thermal conductivity kubonakala, kunika i-crucible phantse i-non-conductive.Ukongeza, iintanda ezininzi zomphezulu ziyakhula, kwaye ukuguquka kombala kwenzeka kumphezulu we-crucible ngenxa ye-oxidation.

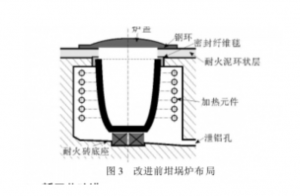

Ekuhloleni isithando somlilo, njengoko kubonisiwe kuMfanekiso 3, isiseko esenziwe ngezitena ezipakishweyo sisetyenziswa, kunye neyona nto isezantsi yokufudumeza yocingo oluchasayo olubekwe kwi-100 mm ngaphezu kwesiseko.Umphezulu we-crucible uvalwe kusetyenziswa iingubo ze-asbestos zefiber, ezibekwe malunga ne-50 mm ukusuka kumphetho ongaphandle, ezibonisa ukukrazula okubalulekileyo kumphetho ongaphakathi we-crucible top.

2. Uphuculo olutsha lobuchwephesha

Uphuculo loku-1: Ukwamkelwa kwe-Isostatic Cinezelwe yodongwe lwe-Graphite Crucible (nge-Low-Temperature Oxidation Resistant Glaze)

Ukusetyenziswa kwesi crucible kwandisa kakhulu ukusetyenziswa kwayo kwiziko lokugquma i-aluminium ialloy insulation, ngakumbi malunga nokumelana ne-oxidation.Iikhrayibhile zegraphite zikholisa ukwenza i-oxidize kumaqondo obushushu angaphezu kwe-400 ℃, ngelixa iqondo lobushushu le-aluminiyam ye-alloy furnaces liphakathi kwe-650 kunye ne-700 ℃.Iikhrayibhili ezinobushushu obuphantsi obukwazi ukumelana ne-oxidation zinokucothisa ngokusebenzayo inkqubo ye-oxidation kumaqondo obushushu angaphezu kwama-600 ℃, iqinisekisa ukuhanjiswa kwe-thermal okugqwesileyo.Ngaxeshanye, ikhusela ukunciphisa amandla ngenxa ye-oxidation, ukwandisa ixesha lokuphila le-crucible.

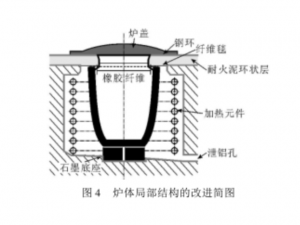

Uphuculo lwesi-2: Isiseko seSithando sokuSebenzisa iGraphite yeMathiriyeli efanayo neCrucible

Njengoko kuboniswe kwi-Figure 4, ukusebenzisa isiseko segraphite yezinto ezifanayo njenge-crucible iqinisekisa ukufudumeza okufanayo kwe-crucible ezantsi ngexesha lokufudumala.Oku kunciphisa iqondo lobushushu elibangelwa kukufudumeza okungalinganiyo kwaye kunciphisa utyekelo lokuqhekeka okuvela kubushushu obungalinganiyo obusezantsi.Isiseko segraphite esizinikezeleyo sikwaqinisekisa inkxaso ezinzileyo kwi-crucible, ukulungelelanisa nezantsi kwayo kunye nokunciphisa iifractures ezibangelwa uxinzelelo.

Uphuculo lwesi-3: Ukwandiswa koLwakhiwo lweNgingqi lweZiko (Umfanekiso 4)

- Ukuphuculwa komphetho ongaphakathi wesigqubuthelo sesithando somlilo, ukuthintela ngokufanelekileyo ukuguga kumphezulu we-crucible kunye nokuphucula ngokubonakalayo ukutywinwa kwesithando somlilo.

- Ukuqinisekisa ukuba ucingo lokuxhathisa lukwinqanaba kunye nomzantsi we-crucible, kuqinisekisa ukufudumeza okwaneleyo komzantsi.

- Ukunciphisa impembelelo ye-fiber blanket seals kwi-crucible heat heat, ukuqinisekisa ukufudumeza okwaneleyo kwi-crucible top kunye nokunciphisa imiphumo ye-oxidation yobushushu obuphantsi.

Ukuphuculwa kwe-4: Ukucokisa Iinkqubo zokuSetyenziswa kwe-Crucible

Ngaphambi kokusetyenziswa, fudumeza i-crucible kwiziko kumaqondo obushushu angaphantsi kwe-200 ℃ kwiiyure ezi-1-2 ukuphelisa ukufuma.Emva kokufudumeza kwangaphambili, nyusa ngokukhawuleza iqondo lobushushu ukuya kuma-850-900 ℃, unciphise ixesha lokuhlala phakathi kwe-300-600 ℃ ukunciphisa i-oxidation phakathi kolu luhlu lobushushu.Emva koko, yehlisa iqondo lobushushu ukuya kubushushu bokusebenza kwaye ungenise imathiriyeli ye-aluminiyam engamanzi ekusebenzeni okuqhelekileyo.

Ngenxa yeziphumo ezonakalisayo ze-ejenti zokucokisa kwii-crucibles, landela imigaqo yokusetyenziswa echanekileyo.Ukususwa kwe-slag rhoqo kubalulekile kwaye kufuneka kwenziwe xa i-crucible ishushu, njengoko ukucoca i-slag kuba ngumngeni ngenye indlela.Ukuqwalaselwa ngokucokisekileyo kwe-crucible's conductivity ye-thermal kunye nobukho bokuguga kwiindonga ezinqamlekileyo kubalulekile kwiinqanaba zokugqibela zokusetyenziswa.Ukutshintshwa ngexesha elifanelekileyo kufuneka kwenziwe ukuthintela ukulahleka kwamandla ngokungeyomfuneko kunye nokuvuza kolwelo lwe-aluminiyam.

3. Iziphumo zoPhuculo

Ubomi obandisiweyo be-crucible ephuculweyo buphawuleka, ukugcina ukuhanjiswa kwe-thermal ixesha elide, ngaphandle kokuqhekeka komphezulu kubonwa.Ingxelo yomsebenzisi ibonisa ukusebenza okuphuculweyo, kungekuphela nje ukunciphisa iindleko zemveliso kodwa nokuphucula kakhulu ukusebenza kakuhle kwemveliso.

4. Isiphelo

- I-Isostatic icinezelwe ngodongwe lwe-graphite crucibles idlula i-crucibles yendabuko ngokwemigaqo yokusebenza.

- Isakhiwo sesithando somlilo kufuneka sihambelane nobukhulu kunye nesakhiwo se-crucible ukuze usebenze ngokufanelekileyo.

- Ukusetyenziswa okufanelekileyo kwe-crucible kwandisa kakhulu ubomi bayo, kulawula ngokufanelekileyo iindleko zemveliso.

Ngophando olucokisekileyo kunye nokulungelelaniswa kwetekhnoloji ye-crucible furnace, ukusebenza okuphuculweyo kunye nexesha lokuphila linegalelo elikhulu ekwandiseni impumelelo yemveliso kunye nokonga iindleko.

Ixesha lokuposa: Dec-24-2023