CNC ipleyiti yegraphite eyenzelwe wena

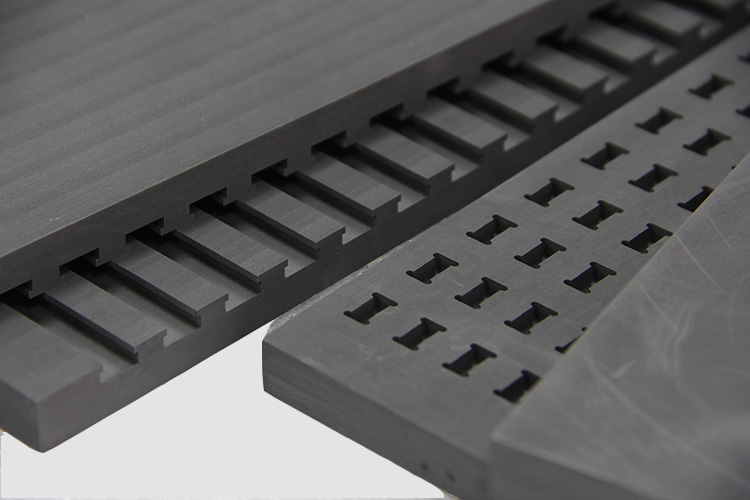

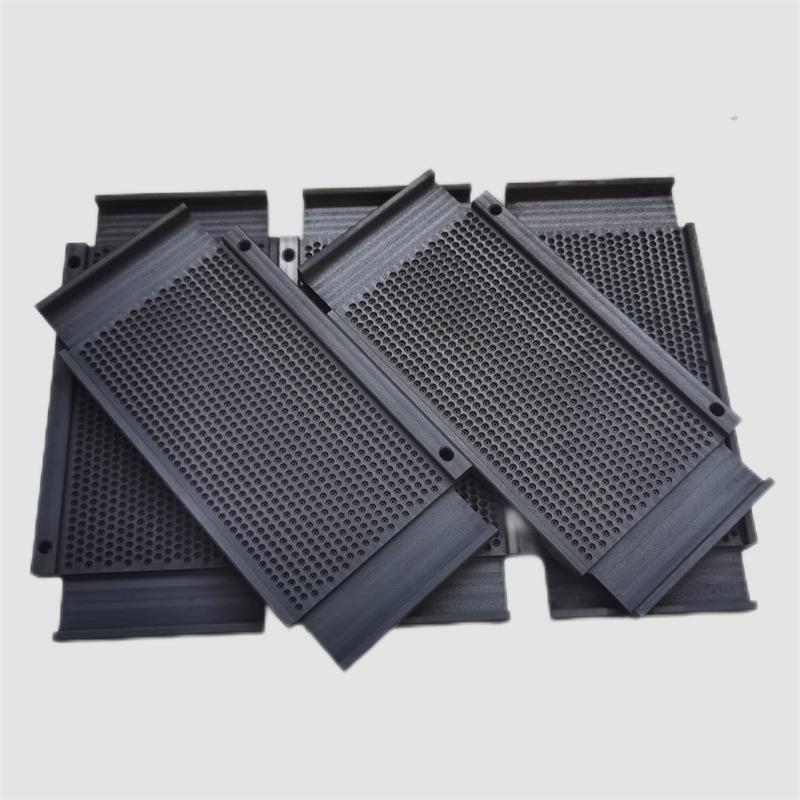

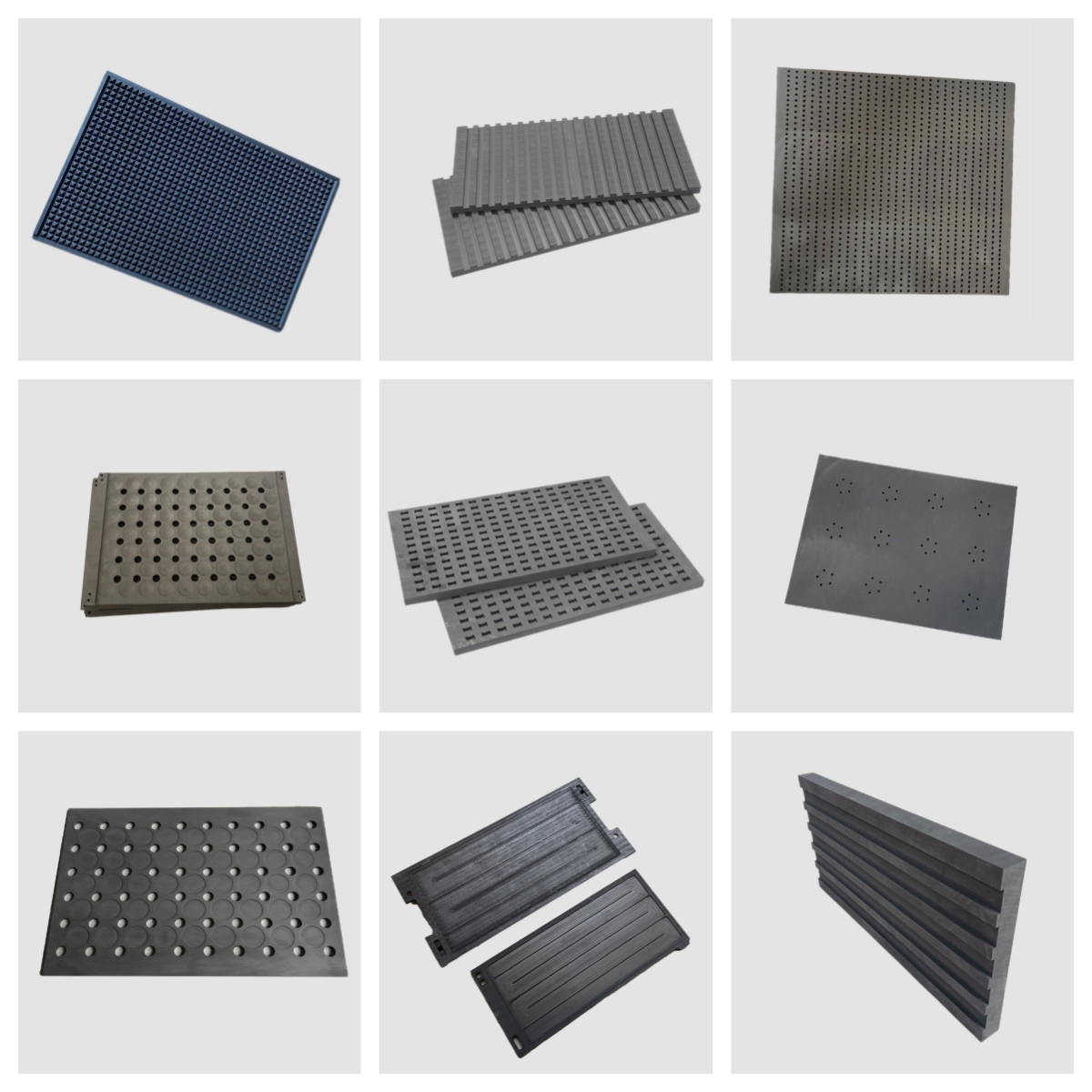

Iimbonakalo

I-1) Izinto eziphikisayo: Kwishishini lokunyibilikisa, iiplati zegraphite zisetyenziselwa ukuvelisa ii-graphite crucibles, njengama-agent akhuselayo kwii-ingots zetsimbi, kunye nezitena zekhabhoni ze-magnesia kwi-lining of smelting furnaces.

2) Izinto zokuqhuba: Kumashishini ombane, i-graphite isetyenziswa ngokubanzi njenge-electrode, iibrashi, iityhubhu zekhabhoni, kunye neengubo zeetyhubhu zethelevishini.

3) Nxiba izinto ezixhathisayo kunye nezinto zokuthambisa: Kwizixhobo ezininzi zoomatshini, iipleyiti zegraphite zisetyenziswa njengempahla yokunxiba kunye nezinto zokuthambisa, ezinokutyibilika ngesantya esiyi-100m/s ngaphakathi komgangatho wobushushu obuphakathi -200 ukuya kwi-2000 ℃ ngaphandle okanye ngokusetyenziswa okuncinci. ioli yokuthambisa.

I-4) Izinto zokutywina: Sebenzisa i-graphite eguquguqukayo njenge-piston ring gaskets, imisesane yokutywina, njl njl kwiimpompo ze-centrifugal, ii-injini zamanzi, ii-injini zomoya, kunye nezixhobo zokuthutha imidiya eyingozi.

5) Izinto ezinganyangekiyo kwi-Corrosion: Ukusebenzisa iipleyiti zegraphite njengemikhumbi, imibhobho, kunye nezixhobo, inokumelana nokubola kweegesi ezahlukeneyo ezinobungozi kunye nolwelo kwaye isetyenziswa ngokubanzi kumasebe afana nepetroleum, imichiza kunye ne-hydrometallurgy.

I-6) Ukugquma kwe-thermal, ukumelana nobushushu obuphezulu, kunye nezixhobo zokukhusela i-radiation: Iipleyiti zegraphite zingasetyenziswa njengeemodareyitha ze-neutron kwi-reactors zenyukliya, kunye nemilomo, ii-cones zempumlo, izixhobo ze-aerospace, izinto zokukhusela ukushisa, izixhobo zokukhusela i-radiation, njl.

1. I-isotropy elungileyo, iimpawu ezizimeleyo kubungakanani, imilo, kunye nolwalathiso lwesampulu;

2. Ubume obufanayo, ukuxinana, kunye nekhono elinamandla lokulwa ne-antioxidant;

3. Ukuzithambisa okugqwesileyo;

4. Ukumelana kakuhle nokubola kweekhemikhali;

5. Ukuqhuba okuphezulu kwe-thermal kunye nokusebenza kozinzo lwe-thermal;

6. Amandla aneleyo omatshini kunye nokuchasana kwempembelelo;

7. Kulula kumatshini kwaye inokucutshungulwa kwiimilo ezahlukeneyo zejometri ngokweemfuno.

Xa usebenzisa impompo entsha, nikela ingqalelo kwisalathiso semoto kwaye ugweme ukuyidibanisa umva igiya.Ukujikeleza okubuyela emva kwexesha elide kwempompo kuya kulimaza iiblades.

Uthuli olugqithisileyo kwindawo yokusebenza yempompo kunye nokungacoceki komoya okungonelanga kunokukhawulezisa ukunxiba kwe-blade kunye nokunciphisa ubomi be-blade.

Ubume obumanzi bunokubangela ukubola kwiincakuba kunye neendonga ze-rotor slot.Xa uqalisa impompo yomoya, iinqununu ze-blade akufanele ziphonswe ngaphandle, njengoko uxinzelelo olungalinganiyo lungonakalisa ii-blades.Kwiimeko ezinjalo, ii-blades kufuneka zihlolwe kwaye zicocwe kuqala.

Ukutshintsha rhoqo ngelixa usebenzisa ipompo kwandisa inani leempembelelo ngexesha lokukhupha i-blade, ukunciphisa ixesha lokuphila kwee-blades.

Umgangatho ongalunganga we-blade unokubangela ukunciphisa ukusebenza kwempompo okanye umonakalo kwiindonga ze-cylinder, ngoko kufuneka kugwenywe.

1. Ubuchule bokusebenza obunamandla, obukwazi ukubonelela ngeenkcukacha ezahlukeneyo kunye neeplati zegraphite ezidibeneyo.

2. Sinokubonelela ngeemveliso zegraphite zokubumba i-extrusion, ukubunjwa kwe-vibration, ukubumba, kunye ne-isostatic yokucofa ukubumba njengoko kufuneka.

3. Ngokweemfuno ezahlukeneyo zobugcisa, iimveliso zegraphite ezifana neepleyiti zegraphite zinokuthi zixhomekeke kunyango lokumelana ne-oxidation, unyango olungenakunyakaziswa, kunye nokuqiniswa kwonyango ukuphucula ukusebenza kunye nobomi benkonzo.