ICarbon Bonded Silicon Carbide Crucibles

Iimbonakalo

Iintsimbi ezinyibilikayo kunye ne-alloys: I-Graphite SiC Crucibles isetyenziswa kwiintsimbi ezinyibilikayo kunye ne-alloys, kubandakanywa ubhedu, i-aluminiyam, i-zinc, igolide kunye nesilivere.I-conductivity ephezulu ye-thermal ye-graphite ye-SiC crucibles iqinisekisa ukuhanjiswa kobushushu okukhawulezayo kunye okufanayo, ngelixa indawo ephezulu yokunyibilika kwe-SiC inikezela ukuzinza kwe-thermal kunye nokuchasana nokutshatyalaliswa kwe-thermal.

Ukwenziwa kweSemiconductor: Iicrucible zeGraphite SiC zinokusetyenziselwa ukwenza ii-wafers zesemiconductor kunye namanye amacandelo e-elektroniki.I-Graphite SiC Crucibles 'i-thermal conductivity ephezulu kunye nokuzinza kubenza balungele ukusetyenziswa kwiinkqubo eziphezulu zokushisa ezifana nokubekwa komphunga wekhemikhali kunye nokukhula kwekristale.

Uphando kunye nophuhliso: Iicrucible ze-Graphite SiC zisetyenziswa kuphando lwezenzululwazi kunye nophuhliso, apho ubunyulu kunye nokuzinza kubalulekile.Zisetyenziswa ekudityanisweni kwezinto eziphambili ezifana neeseramics, iicomposites, kunye nealloys.

I-1.Umgangatho wezinto eziphathekayo: Ii-SiC Crucibles zethu zenziwe ngokusebenzisa izinto ezisemgangathweni ophezulu.

I-2.Amandla aphezulu omatshini: Ii-crucibles zethu zinamandla omatshini aphezulu kumaqondo okushisa aphezulu, aqinisekisa ukuhlala kunye nokuphila ixesha elide.

I-3.Ukusebenza kakuhle kwe-thermal: Ii-crucibles zethu ze-SiC zibonelela ngokusebenza kakuhle kwe-thermal, ukuqinisekisa ukuba izinto zakho ziyanyibilika ngokukhawuleza nangempumelelo.

Iimpawu ze-4.Anti-corrosion: Ii-Crucibles zethu ze-SiC zinezixhobo ezichasene ne-corrosion, nakwiqondo lokushisa eliphezulu.

I-5.I-insulation ye-insulation resistance: I-crucibles yethu ine-insulation ye-insulation yombane egqwesileyo, ukukhusela nayiphi na umonakalo onokwenzeka wombane.

I-6.Inkxaso yeteknoloji yobuchwephesha: Sinikezela ngeteknoloji yobuchwephesha ukuxhasa abathengi bethu banelisekile ngokuthenga kwabo.

I-7.Ukwenza ngokwezifiso okukhoyo: Sibonelela ngeendlela zokwenza ngokwezifiso kubathengi bethu.

I-Silicon carbide crucible, ekwabizwa ngokuba yi-carbon bonded silicon carbide crucible, sisikhongozeli esiyimfuneko esisetyenziswa kakhulu kwiilabhoratri kunye neenkqubo ezahlukeneyo zemveliso yemizi-mveliso.Ezi crucibles zenziwe nge-silicon carbide material kwaye zikwazi ukumelana nobushushu obuphezulu, i-oxidation kunye ne-corrosion.Oku, kwakhona, kuvumela i-crucible ukuba imelane nokugqoka kunye ne-corrosion naphantsi kweemeko eziphezulu zokushisa.

Enye yeempawu eziphawulekayo ze-silicon carbide crucibles kukungangeni kweekhemikhali.Zikwanazo neempawu ezibalaseleyo zokugquma umbane kwaye zibonisa ukuhanjiswa kwe-thermal.Ezi crucibles ziyakwazi ukumelana nobushushu kumaqondo okushisa angaphezu kwe-2000 ° C, zizenza zilungele ukuzimisela kwendawo yokunyibilika kunye novavanyo lonyango lobushushu olubandakanya izinto zokushisa eziphezulu kakhulu okanye ii-reagents zekhemikhali.

I-silicon carbide crucibles isetyenziswa ngokubanzi kwiinkalo ezahlukeneyo.Kwiilabhoratri zekhemistri, zihlala zisetyenziselwa ukuphendula kobushushu obuphezulu kunye novavanyo.Olunye usetyenziso oluthile lubandakanya ukulungiswa kweesampulu ezityhidiweyo, ukunyibilika kweentsinga zeglasi ezikhethekileyo, kunye nokulungiswa kwesilica edityanisiweyo.Basenokuququzelela iinkqubo ezifana nokuphosa, ukutshisa kunye nonyango lokushisa.

Ukongeza kwizicelo zaselabhoratri, ii-silicon carbide crucibles nazo zidlala indima ebalulekileyo kwimveliso yemizi-mveliso.Kwimimandla yokunyibilika kwensimbi, ukuveliswa kwesinyithi, ukusetyenzwa kwe-semiconductor, ukusetyenzwa kwezinto ze-polymer kunye nezinye iindawo, i-crucible sisixhobo esiyimfuneko.

Xa usebenzisa i-silicon carbide crucibles, kukho izilumkiso ekufuneka zithathwe ukuqinisekisa ukusebenza kakuhle:

1. Ngaphambi kokusetyenziswa kokuqala, i-crucible kufuneka ihlambuluke ngokucokisekileyo kwaye ifudunyezwe kwindawo yokushisa kwe-200℃-300℃ kwiiyure ezingama-2-3.Le nkqubo iphelisa nakuphi na ukungcola okuseleyo kunye nomswakama, ukunciphisa umngcipheko womonakalo obangelwa ukwanda kwe-thermal kunye nokunciphisa.

2. Xa ubeka izinto kwi-crucible for processing, ungadluli umthamo we-crucible.Oku kuqinisekisa ukujikeleza okufanelekileyo komoya ngaphakathi kwesithando somlilo kwaye kuqinisekisa ukusabela okufanayo kwezinto.

3. Ukunyamekela kufuneka kuthathwe xa ubeka i-crucible kwisixhobo sokufudumeza.Ukulawula isantya sokufudumeza kunye neqondo lokushisa kubalulekile ukukhusela ngokukhawuleza okanye ukuguquka kobushushu obugqithisileyo obunokubangela umonakalo onokuthi ubangele.

Isishwankathelo, i-silicon carbide crucibles zizixhobo eziguquguqukayo kwaye zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.Ezi crucibles zibonelela ngokumelana ne-thermal egqwesileyo kunye nokungangeni kweekhemikhali, ukubonelela ngendlela ethembekileyo nesebenzayo yokuqhuba ukusabela kobushushu obuphezulu kunye novavanyo.Ukusetyenziswa ngokuchanekileyo kunye nokunyamekela kuqinisekisa ukusebenza ngokufanelekileyo kunye nokwandisa ubomi benkonzo yezi crucibles ziyimfuneko.

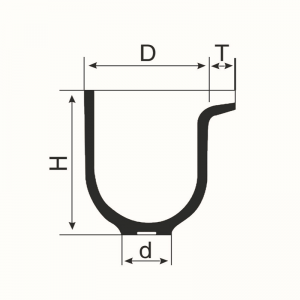

| Into | Ububanzi bangaphandle | Ubude | Ngaphakathi Ububanzi | Ububanzi obusezantsi |

| Z803 | 620 | 800 | 536 | 355 |

| Z1800 | 780 | 900 | 680 | 440 |

| Z2300 | 880 | 1000 | 780 | 330 |

| Z2700 | 880 | 1175 | 780 | 360 |