IiCrucible zeSilicon zeGraphite zeAluminiyam yokuCasa isanti

IIMPAWU ZEMVELISO

I-Superior Thermal Conductivity

Umxube oyingqayizivele we-silicon carbide kunye negraphite iqinisekisa ukufudumeza ngokukhawuleza kunye okufanayo, ukunciphisa kakhulu ixesha lokunyibilika.

Ukumelana nobushushu obugqithisileyo

Umxube oyingqayizivele we-silicon carbide kunye negraphite iqinisekisa ukufudumeza ngokukhawuleza kunye okufanayo, ukunciphisa kakhulu ixesha lokunyibilika.

Ukunyangwa koMhlwa okuZinzileyo

Umxube oyingqayizivele we-silicon carbide kunye negraphite iqinisekisa ukufudumeza ngokukhawuleza kunye okufanayo, ukunciphisa kakhulu ixesha lokunyibilika.

INGCACISO YOBUGCISA

| Igraphite / % | 41.49 |

| I-SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Uxinaniso oluninzi / g·cm⁻³ | 2.20 |

| I-porosity ebonakalayo / % | 10.8 |

| Amandla okutyumza/MPa (25℃) | 28.4 |

| Imodyuli yokugqabhuka/ MPa (25℃) | 9.5 |

| Ubushushu bokumelana nomlilo/ ℃ | >1680 |

| Ukumelana nokothuka kweThermal / Amaxesha | 100 |

| Ubume/Ifomu | A (mm) | B (mm) | C (mm) | D (mm) | E x F max (mm) | G x H (mm) |

|---|---|---|---|---|---|---|

| A | 650 | 255 | 200 | 200 | 200x255 | Ngesicelo |

| A | 1050 | 440 | 360 | 170 | 380x440 | Ngesicelo |

| B | 1050 | 440 | 360 | 220 | ⌀380 | Ngesicelo |

| B | 1050 | 440 | 360 | 245 | ⌀440 | Ngesicelo |

| A | 1500 | 520 | 430 | 240 | 400x520 | Ngesicelo |

| B | 1500 | 520 | 430 | 240 | ⌀400 | Ngesicelo |

UKUQHUBEKA KWENKQUBO

1. Ukuqulunqwa okuchanekileyo

Ucoceko oluphezulu lwegraphite + iprimiyamu yesilicon carbide + iarhente ebophelelayo yobunini.

.

2.Isostatic Pressing

Uxinaniso ukuya kuthi ga kwi-2.2g/cm³ | Ukunyamezela kobunzima bodonga ± 0.3m

.

3.High-Ubushushu Sintering

I-SiC particle recrystallization yenza isakhiwo se-3D yenethiwekhi

.

4. Ukuphuculwa komphezulu

I-Anti-oxidation coating → 3 × ukuphuculwa kokuxhathisa kwe-corrosion

.

5.Ukuhlolwa komgangatho ngokungqongqo

Ikhowudi yokulandelela eyodwa yokulandeleka ngokupheleleyo komjikelo wobomi

.

6.Ukupakishwa koKhuseleko

Umaleko wokufunxa ukothuka + Isithintelo sokufuma + Isingxobo esomeleziweyo

.

ISICELO SEMVELISO

Iziko lokunyibilika kwegesi

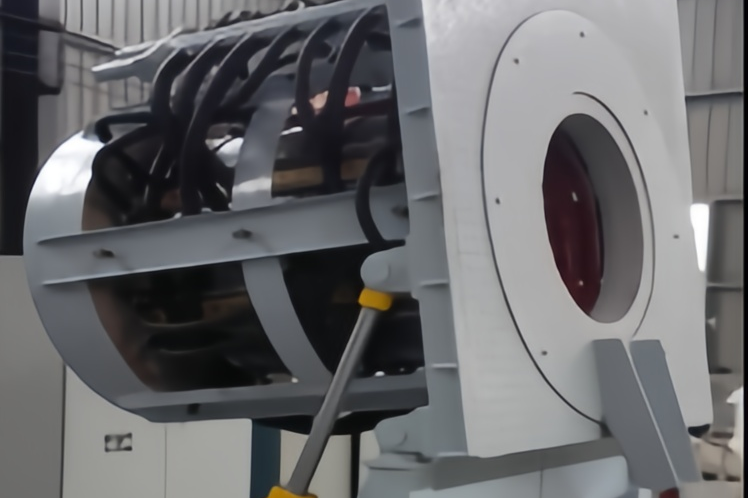

I-Induction Melting Furnace

I-Resistance Melting Furnace

KUTHENI USIKHETHE

FAQS

I-Q1: Ziziphi iingenelo ze-silicon carbide graphite crucibles xa kuthelekiswa ne-graphite crucibles yendabuko?

✅Ukumelana nobushushu obuphezulu: Inokumelana ne-1800 ° C ixesha elide kunye ne-2200 ° C yexesha elifutshane (vs. ≤1600 ° C yegraphite).

✅Ubomi Obude: I-5x engcono yokuxhathisa ukothuka kwe-thermal, 3-5x ubude benkonzo yomndilili wenkonzo.

✅Zero Usulelo: Akukho ukungena kwekhabhoni, ukuqinisekisa ukucoceka kwesinyithi esinyibilikisiweyo.

I-Q2: Zeziphi izinyithi ezinokunyibilikiswa kwezi crucibles?

▸Iintsimbi eziqhelekileyo: Aluminiyam, ubhedu, i-zinc, igolide, isilivere, njl.

▸Iintsimbi ezisebenzayo: I-Lithium, i-sodium, i-calcium (idinga i-Si₃N₄ yokugquma).

▸Iintsimbi eziRefractory: I-Tungsten, i-molybdenum, i-titanium (idinga i-vacuum / igesi ye-inert).

I-Q3: Ngaba ii-crucibles ezintsha zifuna unyango lwangaphambili ngaphambi kokusetyenziswa?

Ukubhaka okunyanzelekileyo: Ukufudumala kancinci ukuya kuma-300 ° C → bamba iiyure ezi-2 (isusa ukufuma okushiyekileyo).

Ingcebiso yokuQala yokuNyibilika: Nyibilikisa ibhetshi yezinto ezilahliweyo kuqala (yenza umaleko okhuselayo).

I-Q4: Ukuthintela njani ukuqhekeka kwe-crucible?

Ungaze uhlawule izinto ezibandayo kwi-crucible eshushu (max ΔT <400 ° C).

Izinga lokupholisa emva kokunyibilika <200 ° C / ngeyure.

Sebenzisa i-crucible tongs ezinikezelweyo (ukuphepha impembelelo yomatshini).

Q5: Ukuthintela njani ukuqhekeka kwe-crucible?

Ungaze uhlawule izinto ezibandayo kwi-crucible eshushu (max ΔT <400 ° C).

Izinga lokupholisa emva kokunyibilika <200 ° C / ngeyure.

Sebenzisa i-crucible tongs ezinikezelweyo (ukuphepha impembelelo yomatshini).

Q6: Yintoni ubungakanani obuncinci bomyalelo (MOQ)?

Iimodeli ezisemgangathweni: Iqhekeza eli-1 (iisampulu zikhoyo).

Uyilo lweSiko: Iziqwenga ze-10 (imidwebo ye-CAD iyadingeka).

Q7: Lithini ixesha lokuhamba?

⏳Izinto ezikwiStokhwe: Ngenqanawa kwiiyure ezingama-48.

⏳Imiyalelo yesiko: 15-25iintsukukwimveliso kunye neentsuku ezingama-20 zokungunda.

Q8: Indlela yokufumanisa ukuba i-crucible ayiphumelelanga?

Iintanda> 5mm kudonga lwangaphakathi.

Ubunzulu bokungena kwesinyithi> 2mm.

Ukuguqulwa > i-3% (ukulinganisa ukutshintshwa kwedamitha yangaphandle).

Q9: Ngaba uyasibonelela ngesikhokelo senkqubo yokunyibilika?

Ukufudumeza amagophe kwiintsimbi ezahlukeneyo.

Isibali-manani sokuhamba kwerhasi engasebenziyo.

Ukususwa kwe-slag izifundo zevidiyo.