Kukho umahluko okhoyo phakathiI-Silicon Carbide thercabskunye negrafiti yokubethelelwa kwiinkalo ezininzi ezinje ngezixhobo, iinkqubo, ukusebenza kunye namaxabiso. Lo mahluko awuchaphazeli inkqubo yayo yokwenziwa, kodwa ikwalungisa ukusebenza kwalo kunye nemeko yesicelo.

Umahluko omkhulu

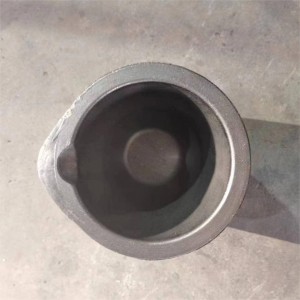

Igrafu ye-graphite yenziwa ikakhulu yegrafu yendalo kwaye isebenzisa udongwe njenge-binder. Oku kudityaniswa kunika igrafu enqabileyo etyetyisiweyo yokuqhubela phambili kwengqondo kunye nokunganyangeki kobushushu obuphezulu, okwenza ilungele ukusetyenziswa kwiinkqubo zobushushu obukhulu. Isakhiwo esahlukileyo kunye nokuphumelela okuphezulu kwe-rake ye-Flake yendalo esenza i-graphite i-grameli idume kakhulu kumashishini e-metserunical kunye nezonyango.

I-Silicon Carbide entle isekwe kwi-FAKE ye-FAKE ye-FAKELE I-ECLAKE, nge-Silicon carbide njengeyona nto iphambili kunye neqondo lobushushu obuphezulu njengabambisi. Njengezinto ezingaqhelekanga, i-silicon carbide inxibe kakhulu ukuzinza okukhulu kunye nokuzinza kobushushu, ukuvumela ukuba kubekho iimbeko ze-silicon carbles ukuba zisetyenziswe kwiindawo ezinobunzima. Ukusetyenziswa kweqondo lobushushu obuphezulu kukwandisa amandla apheleleyo kunye nokuqina.

Inkqubo yokuqhutywa

Inkqubo yokwenziwa kwegrafiti ixhomekeke ikakhulu kwi-Manual kunye noomatshini bokucinezela. I-grafitite yegraphite yegraphite yenziwa ngokubanzi ngoomatshini bokucinezela, emva koko basongelwe kwi-kiln kubushushu obu-1 000 degrees, kwaye ekugqibeleni bahlanganiswe nge-anti-comp-upeyili ye-anti-ipeyinti yokwandisa ukuqina kunye nokunganyangeki kobungqina. Le nkqubo yesiko, ngelixa isebenza ngendleko, inomda ngokubhekisele ekusebenzeni kokusebenza kunye nokungqinelana komgangatho.

Inkqubo yemveliso ye-Silicon Carbide ithelekiseka kakhulu, isebenzisa izixhobo ze-isostatic kunye nefomula yenzululwazi. Itekhnoloji ye-Isostatic isebenza ngoxinzelelo lwe-iyunifou (ukuya kuthi ga kwi-150 MPA), kukhokelela kwixesha eliphezulu kunye nokungaguquguquki kwezi zinqambile. Le nkqubo ayiphumi nje kuphela amandla omatshini othe tyaba, kodwa ikwandisa kakhulu ukumelana nokungaxhathisi kwakhe kwimothuki ye-shirmal kunye nokucoca.

Umahluko weNtsebenzo

Ngokwendlela yokusebenza, kukho umahluko okhoyo phakathi kwe-greyitives kunye ne-silicon carbides. Igrafu ye-greyitives inezinto ezixineneyo ze-13 KE / CM², ngelixa i-Silicon ye-silicon carbible ine-1.7 ka-26 ka / mm². Inkonzo yobomi begrafiki yegrafiki ihlala i-3-5 izihlandlo ze-silicon carbibles, enokubangelwa kukungaphezulu kwezinto eziphezulu zempahla kunye nokunganyangeki kwe-slicon carbide.

Ukongeza, umahluko weqondo lobushushu phakathi ngaphakathi nangaphandle kwegrafu ebunziweyo malunga ne-35 degrees imalunga nama-35 ngamaqondo omdaka we-Celbic Maked i-2-5 kuphela i-2-5 imbeke ngaphezulu kulawulo lobushushu kunye nozinzo lobushushu. I-Acid kunye ne-Alkali Ukunganyangeki kunye nokunganyangeki kwe-corrosion ye-selicon carbides iphakame kakhulu kunaleyo i-grafite ithe tye, ephucula kakhulu i-50% yamandla ama-50% kune-grafite crubibles.

Umahluko ngexabiso

Ngenxa yemahluko kwizixhobo kunye neenkqubo zemveliso, iidyuli zegrafikhi kunye ne-silicon carbides zinemahluko obalulekileyo. Ngokwesiqhelo, i-selicon carbide i-thercabs imalunga namaxesha amathathu abiza kakhulu kune-grafite cruckeds. Lo mahluko amaxabiso ubonakalisa izibonelelo ezibalulekileyo ze-selicon carbide the the the the the the ndleko zezinto ezibonakalayo, ezenziweyo zenkqubo yokusebenza.

Isishwankathelo, nangona i-Silicon Carbides ixabisa ngaphezulu, ukuqina kwabo okuphezulu, ukunganyangeki, kunye nokusebenza kwamandla kuyenza kube lula ngakumbi kwizicelo ezininzi ezifunwayo. Igrafu Cruibles ihlala isetyenziswa ngokubanzi kwizicelo ezininzi zesintu ngenxa yeendleko zawo ezisezantsi kunye neepropathi ezifanelekileyo ezisisiseko. Izibonelelo ezilungileyo nezingalunganga kwezi nqamleza zimbini imbethe zimisela ukuba zilungele iimeko ezahlukeneyo zesicelo.

Ixesha lokuposa: Jun-13 ukuya ku-2424