Iintsimbi zegraphitezizixhobo ezibalulekileyo kumashishini ahlukeneyo, ngakumbi ekunyibilikiseni isinyithi kunye neenkqubo zokucoca. Nangona kunjalo, ukuphathwa ngokungafanelekanga kunokukhokelela kumonakalo okanye kwiingozi zokhuseleko. Ukuqinisekisa ixesha elide kunye nokusebenza kakuhle kweecrucible zegraphite, kubalulekile ukulandela iindlela zokuphatha ezichanekileyo. Nazi izikhokelo ekufuneka uziqwalasele:

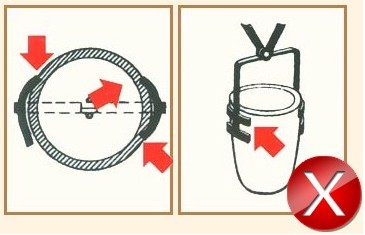

Izenzo ezingachanekanga:

Ukusebenzisa i-tongs ye-crucible undersized crucible tongs kunokubangela i-dents kunye ne-indentation kumphezulu we-crucible, ngakumbi ukuba kusetyenziswe amandla amaninzi ngexesha lokubamba. Ngaphezu koko, ukubeka i-tongs phezulu kakhulu ngelixa ususa i-crucible kwisithando somlilo kunokubangela ukuphuka.

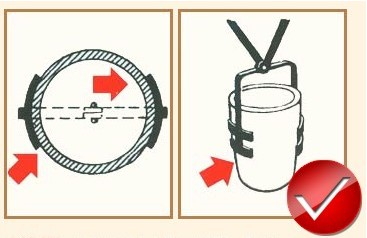

Iinkqubo ezichanekileyo:

Izithawuni ezibethelelwayo kufuneka zilinganiswe ngokufanelekileyo ukuze zihambelane ne-crucible. Izithonga ezingaphantsi kobukhulu kufuneka ziphetshwe. Ukongeza, xa ubamba i-crucible, i-tongs kufuneka ibambe ngaphantsi kancinci embindini ukuqinisekisa ukuba usasazo lwamandla.

Ukuthintela umonakalo owenziwe ngaphambi kwexesha kunye neengozi ezinokubakho, kubalulekile ukuthobela la manyathelo okhuseleko alandelayo:

Imilinganiselo ye-crucible tongs kufuneka ihambelane nobukhulu be-crucible, ukuqinisekisa ukudibanisa okupheleleyo kunye ne-internal crucible.

Isibambo se-tongs akufanele sibe noxinzelelo kwi-rim ephezulu ye-crucible ngexesha lokubamba.

I-crucible kufuneka ibanjwe kancinane ngaphantsi kweziko, ivumele ukuhanjiswa kwamandla afanayo.

Ukwamkelwa kunye nokuPhathwa kweSilicon Carbide Graphite Crucibles

Ukwamkelwa kweMpahla: Emva kokufumana i-silicon carbide graphite crucibles, kubalulekile ukuhlola ukupakishwa kwangaphandle naziphi na iimpawu zomonakalo. Emva kokukhupha, jonga umphezulu we-crucible malunga naziphi na iziphene, iintanda, okanye umonakalo kwi-coating.

Ukuphathwa kweCrucible: Ukuziqhelanisa okungalunganga: Ukuphatha i-crucible ngokuyibetha okanye ukuyiqengqa kunokubangela umonakalo kwi-glaze layer.

Ukuziqhelanisa okuchanekileyo: Izibonda kufuneka ziphathwe ngononophelo kusetyenziswa inqwelo ekhuniweyo okanye izixhobo ezifanelekileyo zokuphatha ukuphepha iimpembelelo, ukungqubana, okanye ukuwa. Ukukhusela umaleko we-glaze, i-crucible kufuneka iphathwe ngobumnene, iqinisekise ukuba iphakanyiswe kwaye ibekwe ngononophelo. Ukuqengqeleka i-crucible emhlabeni ngexesha lokuthutha kufuneka kugwenywe ngokungqongqo. Umaleko we-glaze uchaphazeleka kumonakalo, okukhokelela kwi-oxidation kunye nokuguga ngexesha lokusetyenziswa. Ngoko ke, kucetyiswa ukuba usebenzise inqwelo ekhutshiweyo okanye ezinye izixhobo ezifanelekileyo zokuphatha ukuze kuqinisekiswe ukuthuthwa ngokucophelela kwe-crucible.

Ukugcinwa kweSilicon Carbide kunye neGraphite Clay Crucibles: Ukugcinwa kwee-crucibles kusengozini kakhulu kumonakalo womswakama.

Ukuziqhelanisa okungalunganga: Ukupakisha ii-crucibles ngokuthe ngqo kumgangatho we-samente okanye ukubonakalisa ukufuma ngexesha lokugcinwa okanye ukuthutha.

Ukuziqhelanisa okuchanekileyo:

Ii-crucibles kufuneka zigcinwe kwindawo eyomileyo, ngokukhethekileyo kwiipalati zokhuni, ukuqinisekisa ukungena komoya ofanelekileyo.

Xa izibonda zibekwe zijongise ezantsi, zinokupakishwa ukugcina indawo.

Izibonda zomnqamlezo kufuneka zingaze zibe sesichengeni kwiimeko zokufuma. Ukufunxa ukufuma kunokubangela ukuba umaleko we-glaze uqhume ngexesha lenqanaba lokufudumeza, okukhokelela ekunciphiseni ukusebenza kakuhle kunye nobomi. Kwiimeko ezinzima, i-bottom of the crucible inokuqhawula.

Inkampani yethu igxile kwimveliso ye-silicon carbide graphite crucibles, iicrucibles ezikhethekileyo zealuminium ezinyibilikayo, iicrucibles zegraphite zethusi, iicrucibles zodongwe lwegraphite, iicrucibles zegraphite ezijolise kumazwe angaphandle, abahambisi bephosphorous, iziseko zegraphite crucible, kunye nemikhono ekhuselayo. Iimveliso zethu zikhethwa ngokungqongqo kunye novavanyo, ziqinisekisa ukusebenza ngokugqibeleleyo ukusuka ekukhethweni kwemathiriyeli ekrwada kuzo zonke iinkcukacha zemveliso kunye noyilo lokupakisha.

Ixesha lokuposa: Jun-27-2023