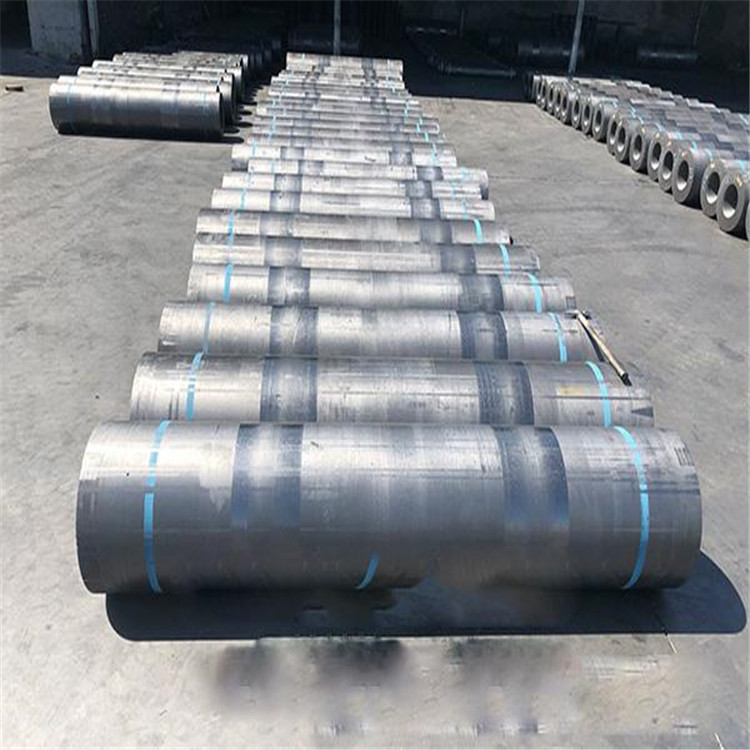

Ii-Electrodes zeGraphite

Ii-electrode zegraphite zisetyenziswa kwishishini lokunyibilikisa umbane kwaye zineempawu ezinje nge-superconductivity, i-thermal conductivity, amandla omatshini aphezulu, ukuxhathisa kwe-oxidation, kunye nobushushu obuphezulu be-corrosion resistance.

I-electrode yethu yegraphite inokumelana okuphantsi, ukuxinana okuphezulu, ukuxhathisa okuphezulu kwe-oxidation, kunye nokuchaneka okuchanekileyo kwe-machining, ngakumbi isulfure ephantsi kunye nomlotha ophantsi, ongayi kuzisa ukungcola okwesibini kwintsimbi.

Igraphite inozinzo oluhle lweekhemikhali. Igraphite enyangwa ngokukodwa ineempawu zokuxhathisa umhlwa, ukuhanjiswa kakuhle kwe-thermal, kunye nokungena kancinci.

I-electrode yegraphite imathiriyeli ekrwada ithatha isulfure ephantsi kunye neCPC yothuthu oluphantsi. Yongeza i-30% yenaliti ye-coke kwi-electrode yebakala le-HP ye-asphalt ye-coking plant. Iielectrode zegraphite ze-UHP zisebenzisa i-100% yenaliti ye-coke kwaye zisetyenziswa kakhulu kwi-LF. I-steel eyenza i-furnace induction, i-oven non-ferrous metal induction. Amashishini e-silicon kunye ne-phosphorus.

| Ubungakanani be-UHP kunye noNyamezelo | ||||||||||||

| Ububanzi (mm) | Ubude (mm) | |||||||||||

| Idayamitha yegama | Eyona dayamitha | Ubude obuqhelekileyo | Ukunyamezelana | Ubude beenyawo ezimfutshane | ||||||||

| mm | intshi | max | imiz | mm | mm | max | imiz | |||||

| 200 | 8 | 209 | 203 | 1800/2000/ 2200/2300 2400/2700 | ±100 | -100 | -275 | |||||

| 250 | 10 | 258 | 252 | |||||||||

| 300 | 12 | 307 | 302 | |||||||||

| 350 | 14 | 357 | 352 | |||||||||

| 400 | 16 | 409 | 403 | |||||||||

| 450 | 18 | 460 | 454 | |||||||||

| 500 | 20 | 511 | 505 | |||||||||

| 550 | 22 | 556 | 553 | |||||||||

| 600 | 24 | 613 | 607 | |||||||||

| Isalathiso soMzimba kunye neMichiza ye-UHP | ||||||||||||

| Izinto | iyunithi | Ububanzi: 300-600mm | ||||||||||

| Umgangatho | Idatha yovavanyo | |||||||||||

| I-Electrode | Ingono | I-Electrode | Ingono | |||||||||

| Ukunganyangeki kombane | μQm | 5.5-6.0 | 5.0 | 5.0-5.8 | 4.5 | |||||||

| Amandla e-Flexure | Mpa | 10.5 | 16 | 14-16 | 18-20 | |||||||

| Imodyuli ye-elasticity | GPA | 14 | 18 | 12 | 14 | |||||||

| Umxholo wothuthu | % | 0.2 | 0.2 | 0.2 | 0.2 | |||||||

| Ukuxinana okubonakalayo | g/cm3 | 1.64-16.5 | 1.70-1,72 | 1.72-1.75 | 1.78 | |||||||

| Into yokwandiswa(100-600℃) | x10-6/°℃ | 1.5 | 1.4 | 1.3 | 1.2 | |||||||

Umbuzo: Kunjani ngokupakisha?

1. Iibhokisi zekhadibhodi eziqhelekileyo zokuthumela ngaphandle / iibhokisi zeplywood

2. Iimpawu zokuthumela ngokwezifiso

3. Ukuba indlela yokupakisha ayikhuselekanga ngokwaneleyo, isebe le-QC liya kuqhuba uhlolo