Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

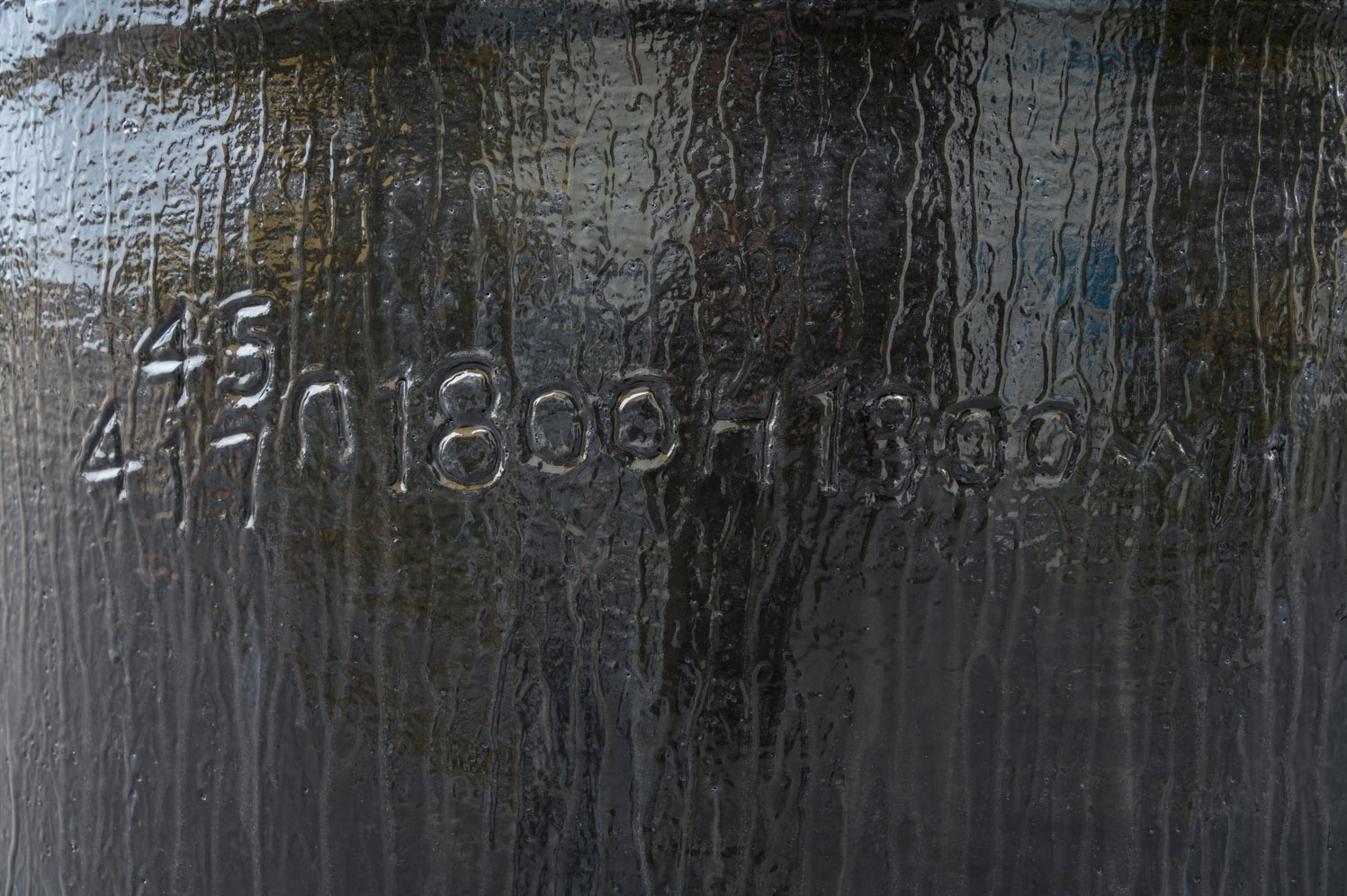

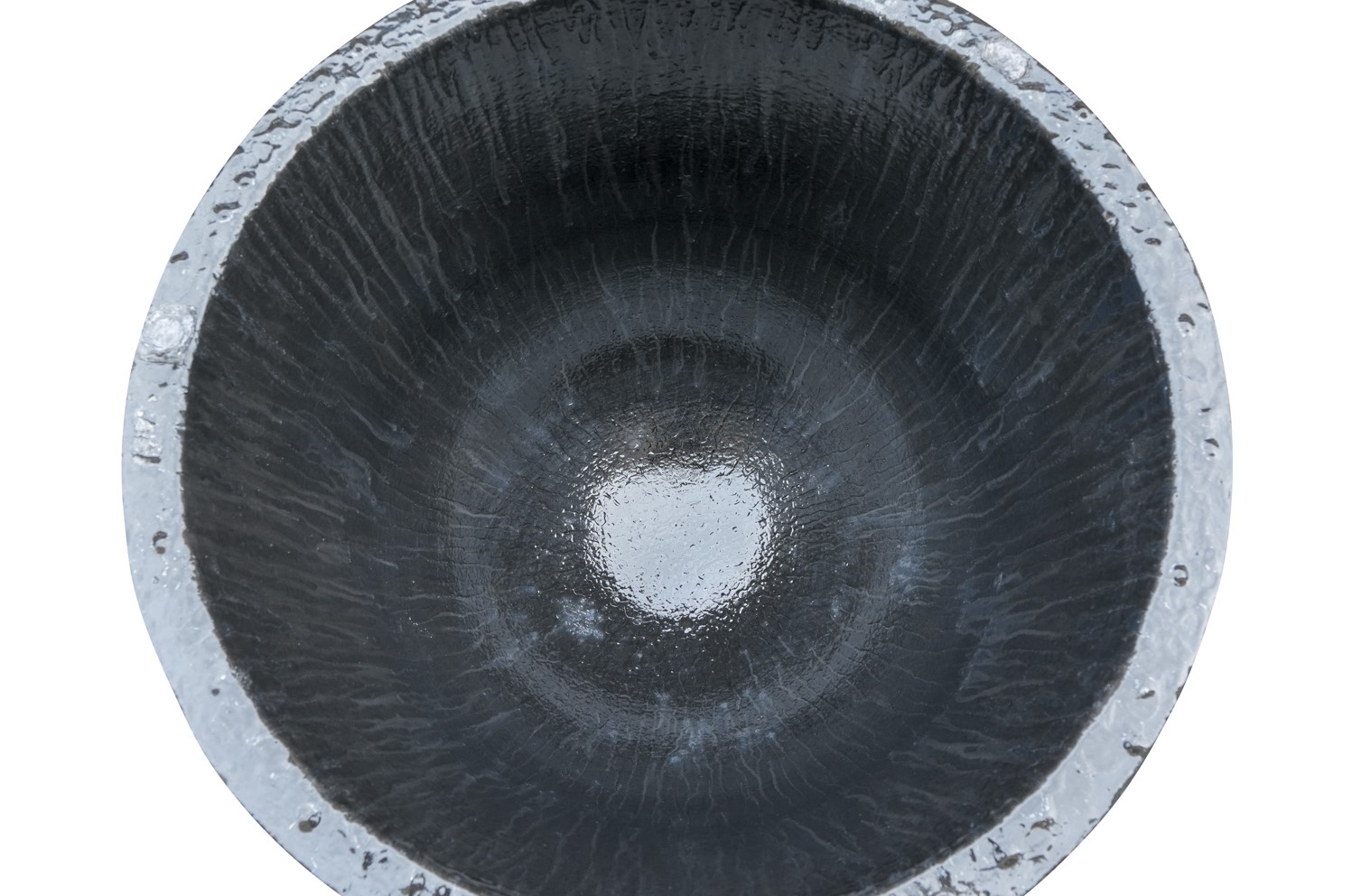

I-Carbon Crucible Idityaniswe negraphite yodongwe yobushushu obuphezulu

IIMPAWU ZEMVELISO

Ukunyibilika ngokukhawuleza

Izinto zegraphite ze-thermal conductivity ziphucula ukusebenza kakuhle kwe-thermal ngama-30%, ukunciphisa kakhulu ixesha lokunyibilika.

I-Superior Thermal Shock Resistance

Itekhnoloji ye-resin-bonding imelana nokufudumeza ngokukhawuleza kunye nokupholisa, ivumela ukutshaja ngokuthe ngqo ngaphandle kokuqhekeka.

Ukuqina Okubalaseleyo

Amandla omatshini aphezulu axhathisa impembelelo yomzimba kunye nokukhukuliseka kweekhemikhali ubomi obude benkonzo.

INGCACISO YOBUGCISA

| Igraphite / % | 41.49 |

| I-SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Uxinaniso oluninzi / g·cm⁻³ | 2.20 |

| I-porosity ebonakalayo / % | 10.8 |

| Amandla okutyumza/MPa (25℃) | 28.4 |

| Imodyuli yokugqabhuka/ MPa (25℃) | 9.5 |

| Ubushushu bokumelana nomlilo/ ℃ | >1680 |

| Ukumelana nokothuka kweThermal / Amaxesha | 100 |

| No | Umzekelo | H | OD | BD |

| I-RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| I-RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| I-RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

UKUQHUBEKA KWENKQUBO

1. Ukuqulunqwa okuchanekileyo

Ucoceko oluphezulu lwegraphite + iprimiyamu yesilicon carbide + iarhente ebophelelayo yobunini.

.

2.Isostatic Pressing

Uxinaniso ukuya kuthi ga kwi-2.2g/cm³ | Ukunyamezela kobunzima bodonga ± 0.3m

.

3.High-Ubushushu Sintering

I-SiC particle recrystallization yenza isakhiwo se-3D yenethiwekhi

.

5.Ukuhlolwa komgangatho ngokungqongqo

Ikhowudi yokulandelela eyodwa yokulandeleka ngokupheleleyo komjikelo wobomi

.

4. Ukuphuculwa komphezulu

I-Anti-oxidation coating → 3 × ukuphuculwa kokuxhathisa kwe-corrosion

.

6.Ukupakishwa koKhuseleko

Umaleko wokufunxa ukothuka + Isithintelo sokufuma + Isingxobo esomeleziweyo

.

ISICELO SEMVELISO

Ifanelekile kwiintsimbi ezininzi ezingenayo i-ferrous

Nyibilikisa iAluminiyam

Nyibilikisa uCopper

Nyibilikisa iGolide

KUTHENI USIKHETHE

FAQS

I-Q1: Ngaba i-Crucible Cover inganciphisa iindleko zamandla?

A: Ngokuqinisekileyo! Inciphisa ukulahleka kobushushu, ukunciphisa ukusetyenziswa kwamandla ukuya kuthi ga kwi-30%.

I-Q2: Ziziphi ii-furnaces ezihambelanayo?

IMPENDULO: Isebenza ngeendlela ezininzi—ifanelekile kwi-induction, igesi, kunye neziko lombane.

I-Q3: Ngaba i-graphite silicon carbide ikhuselekile kubushushu obuphezulu?

A: Ewe. Ukuzinza kwayo kwe-thermal kunye neekhemikhali kwenza ukuba iphelele kwiimeko ezinzima.

I-Q4: Ukuthintela njani ukuqhekeka kwe-crucible?

Ungaze uhlawule izinto ezibandayo kwi-crucible eshushu (max ΔT <400 ° C).

Izinga lokupholisa emva kokunyibilika <200 ° C / ngeyure.

Sebenzisa i-crucible tongs ezinikezelweyo (ukuphepha impembelelo yomatshini).

Q5: Ukuthintela njani ukuqhekeka kwe-crucible?

Ungaze uhlawule izinto ezibandayo kwi-crucible eshushu (max ΔT <400 ° C).

Izinga lokupholisa emva kokunyibilika <200 ° C / ngeyure.

Sebenzisa i-crucible tongs ezinikezelweyo (ukuphepha impembelelo yomatshini).

Q6: Yintoni ubungakanani obuncinci bomyalelo (MOQ)?

Iimodeli ezisemgangathweni: Iqhekeza eli-1 (iisampulu zikhoyo).

Uyilo lweSiko: Iziqwenga ze-10 (imidwebo ye-CAD iyadingeka).

Q7:Sinokuqinisekisa njani umgangatho?

Siqinisekisa umgangatho ngenkqubo yethu yokuhlala sisenza isampuli yangaphambi kokuveliswa ngaphambi kokuveliswa kobuninzi kunye nokuqhuba uhlolo lokugqibela ngaphambi kokuthunyelwa.

I-Q8: Yintoni amandla akho okuvelisa kunye nexesha lokuhambisa?

Umthamo wethu wokuvelisa kunye nexesha lokuhambisa lixhomekeke kwiimveliso ezithile kunye nobungakanani obuyalelweyo. Sisebenza ngokusondeleyo nabathengi bethu ukuqonda iimfuno zabo kwaye sibanike uqikelelo oluchanekileyo lonikezelo.

I-Q9: Ngaba kukho ubuncinci bemfuno yokuthenga ekufuneka ndihlangabezane nayo xa ndiodola iimveliso zakho?

I-MOQ yethu ixhomekeke kwimveliso, zive ukhululekile ukuqhagamshelana nathi ngakumbi.

I-Case Study #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

I-Case Study #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Ubungqina

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. I-Curabitur placerat sodales placerat. I-Nunc dignissim kunye ne-lobortis.

- UJane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. I-Curabitur placerat sodales placerat. I-Nunc dignissim kunye ne-lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- UJohn Doe